Valve control that is more precise and comfortable

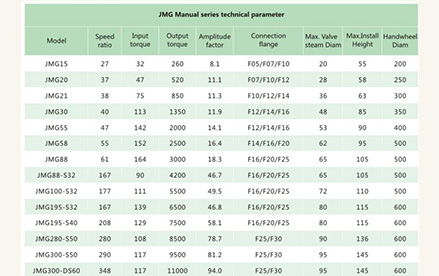

The JMG series rotary valve gearbox with pipe network from Zhejiang Jimai Auto-tech Co., Ltd. is specifically engineered for the installation of certain valves subsurface, as the operating system is vertically designed. The customer has the option of connecting to the JMG series valve gearbox using either a handwheel or an electric actuator. For instance, if the valve is installed one metre underground, the valve gearbox with pipe network is suitable for this operating environment.

CATALOGUE DOWNLOAD

CATALOGUE DOWNLOAD