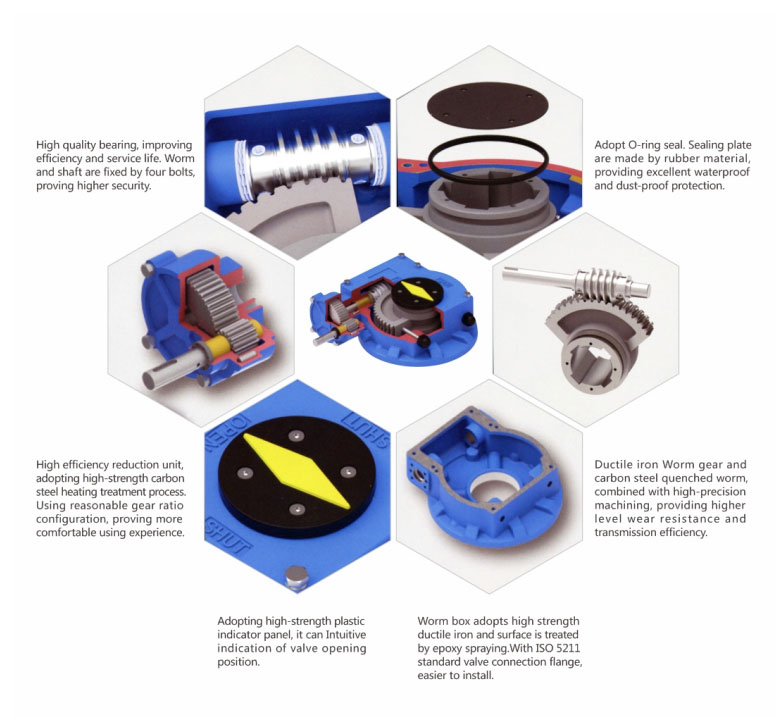

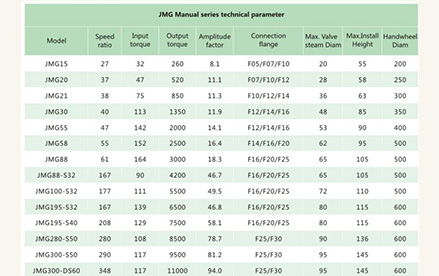

High output torque while only requiring a low input torque

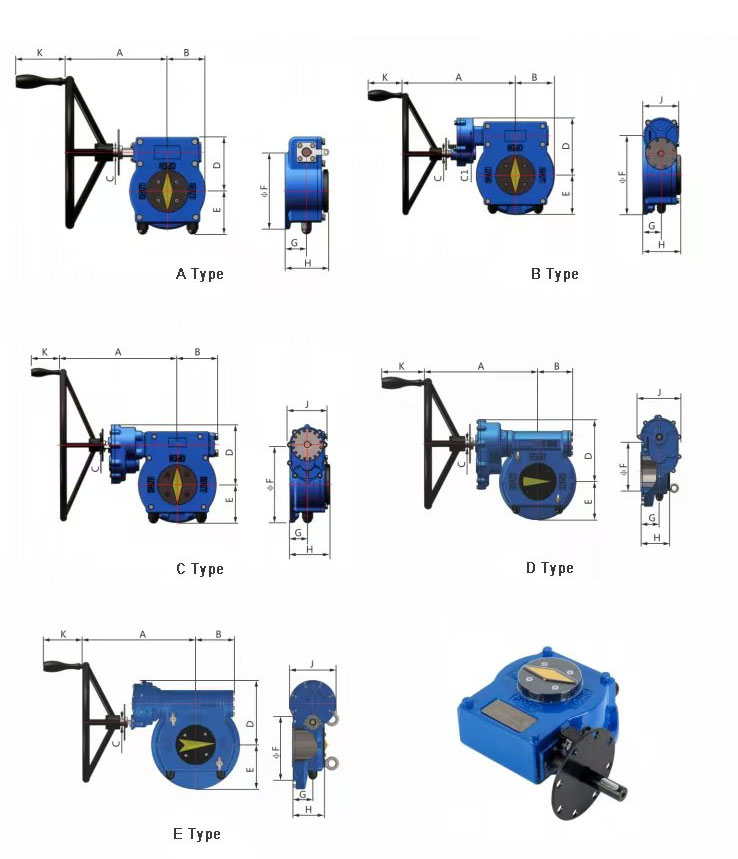

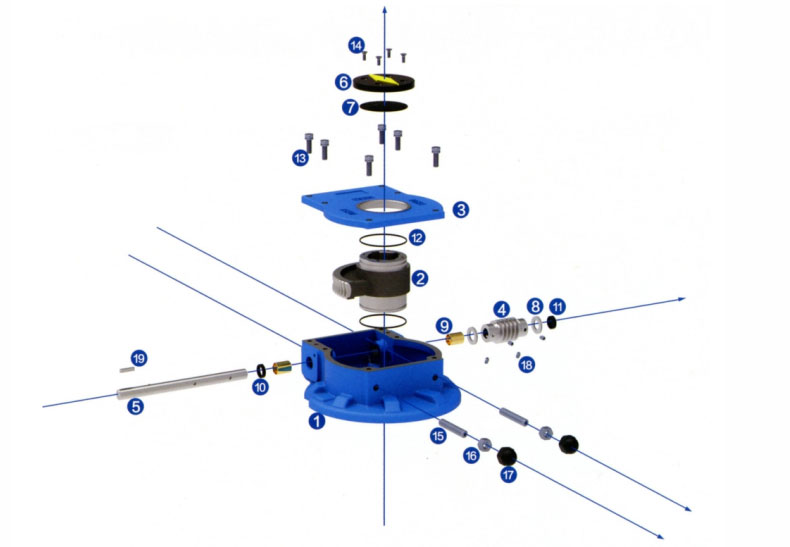

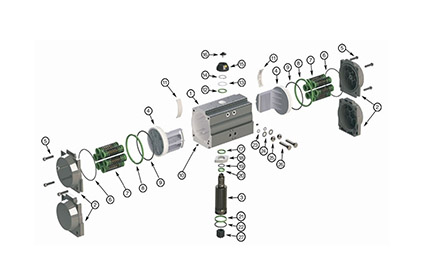

The JMG series rotary valve gearbox from Zhejiang Jimai Auto-tech Co., Ltd. is distinguished by its high transmission efficiency and its reliable self-locking design. Users have the ability to modify the pace ratio in accordance with their actual usage conditions. Additionally, the JMG series rotary valve gearbox is capable of achieving a 90-degree rotation, making it a versatile asset in the field of quarter-turn valves, including butterfly valves and ball valves.

CATALOGUE DOWNLOAD

CATALOGUE DOWNLOAD