Exceptional wear resistance and can significantly prolong the service life

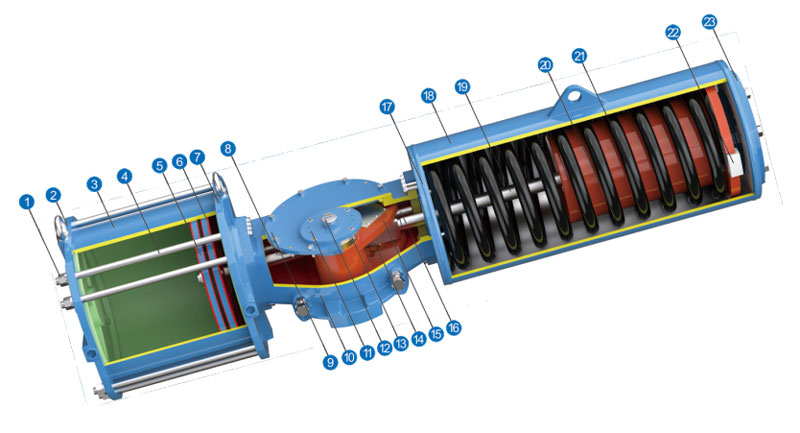

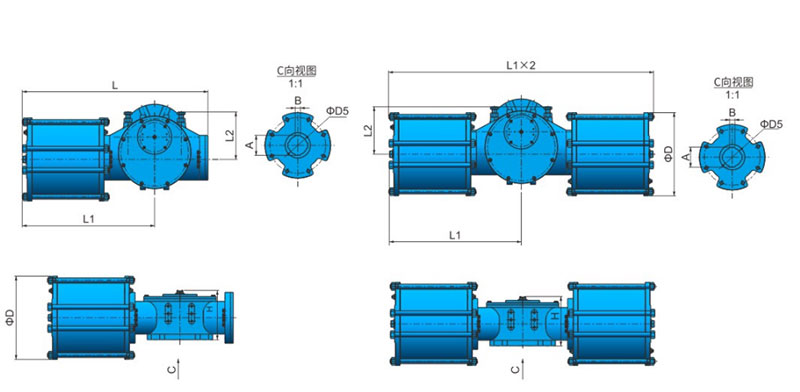

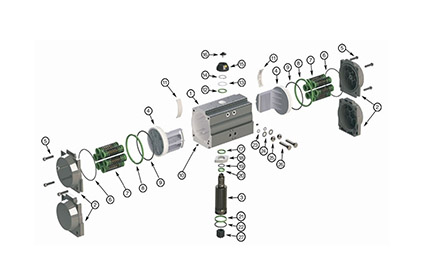

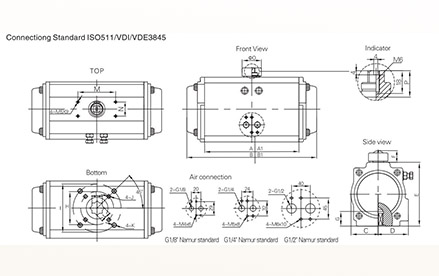

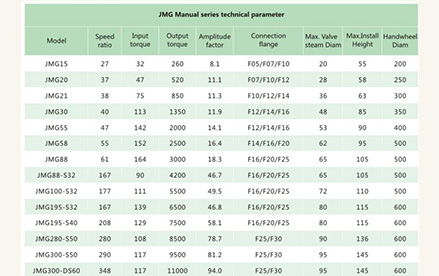

The HXY series scotch yoke pneumatic actuator from Zhejiang Jimai Auto-Tech Co., Ltd. is engineered for high output torque applications in ball and butterfly valves. The maximum output torque for the double acting type can attain 107,847 NM, while the spring return variant can achieve 30,000 NM at 4 bar air pressure, accommodating nearly all operational conditions. The HXY series high torque rotary actuator features a modular construction, allowing each unit to utilize different cylinders and springs to accommodate diverse torque requirements.

CATALOGUE DOWNLOAD

CATALOGUE DOWNLOAD